Enhance Quality Control and Conformity Criteria With Specialist Welding Evaluation Providers

Specialist welding inspection services play an essential function in making certain that these requirements are met with precision and accuracy. As we navigate via the intricacies of welding assessment services, it ends up being evident that the expertise and focus to detail offered by specialists in this area are indispensable for preserving the highest criteria of quality and compliance.

Relevance of Welding Examination Solutions

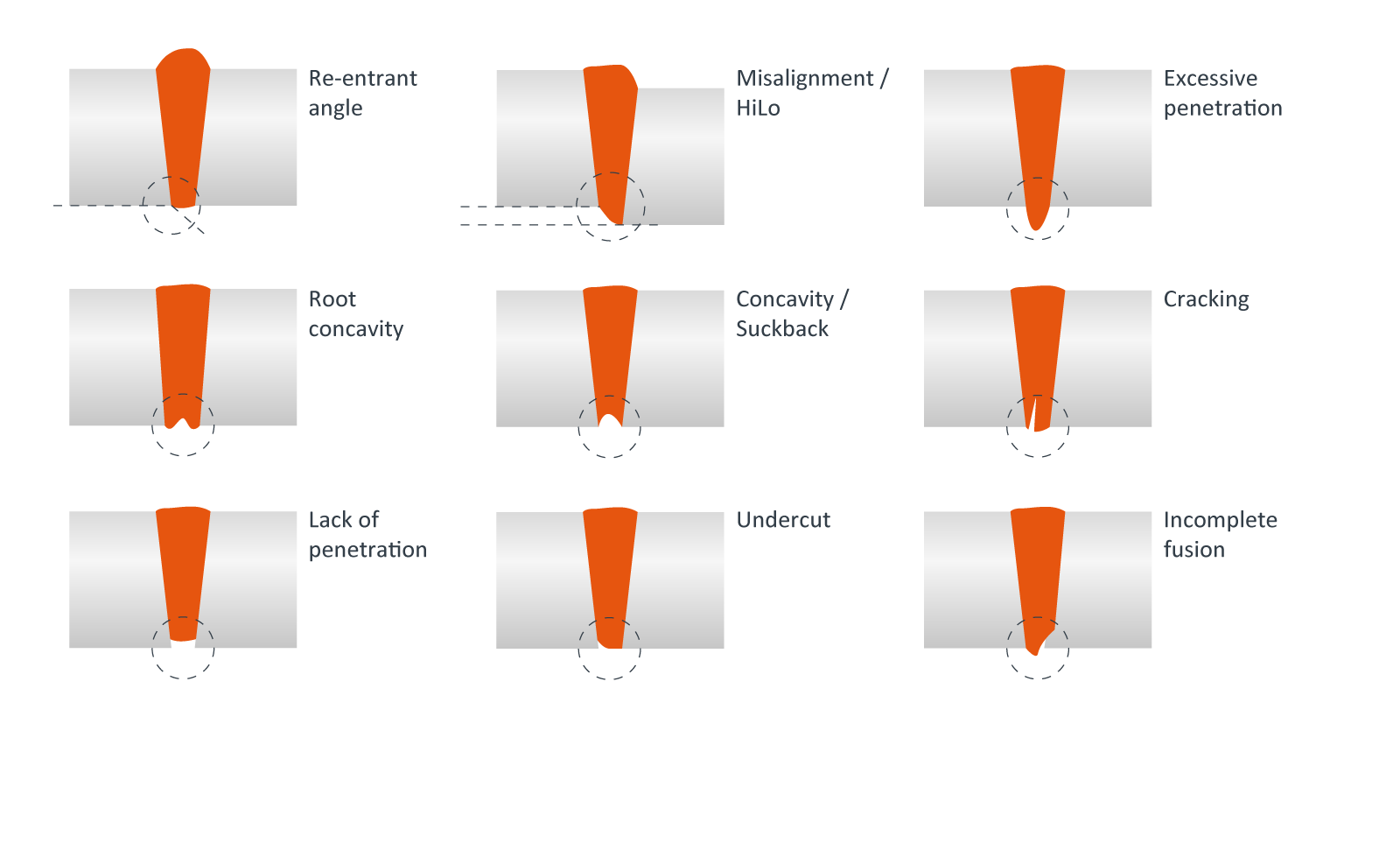

Guaranteeing the high quality and safety and security of bonded frameworks, welding inspection solutions play an essential function in different sectors. By carrying out thorough inspections, these services help in recognizing any welding flaws, gaps, or imperfections that can jeopardize the stability of the structure - Welding Inspection Racine. Welding evaluations are essential for preserving compliance with market criteria and guidelines, in addition to ensuring the longevity and dependability of the welded components

One key relevance of welding evaluation services is the prevention of prospective dangers and mishaps. By spotting welding problems early on, these services help in mitigating threats associated with structural failings, leaks, or other operational issues. In addition, welding inspections help in enhancing the overall efficiency and performance of welded structures, adding to set you back savings and improved efficiency for organizations.

In addition, welding examination services offer a degree of assurance to stakeholders, showing a commitment to quality and safety requirements. Through comprehensive inspections and reporting, these solutions make it possible for companies to construct depend on with clients, regulators, and the basic public, ultimately boosting their reputation and credibility in the marketplace. Finally, the value of welding assessment solutions can not be overemphasized, as they are crucial for supporting quality, security, and compliance in welding procedures throughout markets.

Advantages of Specialist Assessment

Carrying out skilled inspections by competent specialists contributes in revealing possible welding issues and making sure structural stability in different markets. One of the primary advantages of skilled evaluation services is the early detection of welding flaws, which assists avoid pricey rework or fixings down the line. By determining concerns immediately, specialist examiners can recommend rehabilitative activities to attend to the source of the flaws, therefore conserving both time and resources for the company. Furthermore, professional examinations contribute to superior safety standards by guaranteeing that welded elements meet industry policies and quality requirements. This positive strategy not just minimizes the threat of mishaps however likewise develops depend on with clients and stakeholders, showcasing a commitment to supplying reliable and top notch items. Furthermore, professional inspections assist support conformity with appropriate codes and standards, protecting the reputation of the company and fostering a society of excellence in welding practices. On the whole, investing in expert welding inspection services yields lasting benefits by promoting safety and security, efficiency, and adherence to industry ideal methods.

Conformity With Sector Standards

One of the basic pillars of maintaining the structural integrity and quality guarantee in welding procedures is aligning with industry criteria. These requirements are established to regulate the welding procedure, materials used, safety procedures, and general high quality control procedures.

In addition, compliance with sector requirements not only guarantees the security and reliability of welded frameworks yet likewise boosts reliability and trust with clients, regulatory bodies, and other stakeholders. It symbolizes a devotion to excellence and professionalism in welding practices, which can establish a company apart in an affordable market. Generally, lining up with sector requirements is crucial for promoting top quality assurance, accomplishing governing conformity, and fostering a reputation for quality in welding processes.

Enhancing Quality Assurance Steps

Improving weld quality control steps is paramount for making certain the reliability and safety and security of welded frameworks. By improving high quality control measures, firms can decrease issues, article source lower rework, and inevitably deliver exceptional items to their clients. One reliable method to boost quality assurance measures is to execute comprehensive assessment methods throughout the welding procedure. This includes checking resources before welding, checking the welding specifications throughout the procedure, and performing post-weld examinations to find any flaws or flaws.

In addition, purchasing advanced welding technologies and equipment can likewise considerably boost quality assurance steps. Automated welding systems, for instance, can supply even more exact and constant welds contrasted to manual welding procedures - Welding Inspection Racine. Additionally, providing normal training and certification programs for welders can make certain that they are current with the most recent standards and methods, more boosting the quality of welds

Improving Product Safety And Security and Efficiency

Boosting product security and efficiency is important in making sure the dependability and long life of bonded structures. By buying expert welding evaluation solutions, makers can significantly improve the general top quality of their items. Through detailed inspections and adherence to conformity standards, prospective defects or powerlessness in the welding procedure can be recognized and remedied without delay, inevitably improving the security and performance of the last product.

Boosting product security and efficiency is important in making sure the dependability and long life of bonded structures. By buying expert welding evaluation solutions, makers can significantly improve the general top quality of their items. Through detailed inspections and adherence to conformity standards, prospective defects or powerlessness in the welding procedure can be recognized and remedied without delay, inevitably improving the security and performance of the last product.Item security is vital in industries where bonded frameworks are thoroughly used, such as building, automotive, and aerospace. Any type of compromise in the welding stability can lead to tragic repercussions, including architectural failures and security dangers. Therefore, focusing on welding evaluation services not only makes sure compliance with market laws yet additionally imparts self-confidence see this page in the product's dependability and efficiency (Welding Inspection Racine).

Additionally, by proactively addressing any kind of welding problems or variances, makers can improve the general quality of their items, leading to raised client satisfaction and depend on. Improved item safety and security and efficiency also add top article to lasting expense financial savings by decreasing the probability of rework, repairs, or product failings. To conclude, buying expert welding assessment solutions is a proactive technique to ensuring the security, dependability, and performance of welded structures.

Final Thought

To conclude, expert welding examination solutions play a vital function in guaranteeing compliance with sector standards, boosting quality assurance procedures, and enhancing product security and efficiency. With the help of these solutions, business can preserve premium quality assurance levels and fulfill regulative requirements, ultimately bring about much better products and boosted customer complete satisfaction.

As we navigate with the intricacies of welding assessment solutions, it comes to be obvious that the expertise and interest to information offered by experts in this field are crucial for maintaining the highest possible standards of top quality and conformity.

Guaranteeing the quality and safety of welded structures, welding assessment services play a crucial role in different markets.Furthermore, welding examination solutions offer a level of guarantee to stakeholders, demonstrating a dedication to quality and security criteria. In final thought, the significance of welding inspection services can not be overstated, as they are essential for supporting quality, safety, and compliance in welding processes throughout markets.

Automated welding systems, for instance, can give even more constant and exact welds compared to manual welding processes.